CAESAR II®

CAESAR II® accurately evaluates the structural responses and stresses of piping systems, adhering to over 35 international standards. Its ability to analyze complex systems subjected to a wide range of loads makes it an indispensable tool for ensuring plant safety and reliability.

Integration with CAD design packages allows for rapid model import, reducing the risk of errors and the iteration time between company divisions.

CAESAR II® is the industry benchmark for performing comprehensive static and dynamic analyses of piping systems. It enables the precise evaluation of the effects of thermal, weight, pressure, seismic, and other loads to identify and resolve potential stress issues, ensuring compliance with international codes and standards.

This software is aimed at engineers, designers, and stress analysts operating in industrial sectors where the safety and integrity of piping systems are critical. CAESAR II® is the ideal solution for engineering firms, construction companies, manufacturing enterprises, and plant operators.

- Oil & Gas

- Chemicals

- Power Generation (Nuclear, Thermal, Renewable)

- Heavy Industrial Plant Construction

- Heavy Infrastructure Construction

- Machinery and Heavy Equipment

- Utilities and Communications

- Engineering Services

Benefits

Renowned software

CAESAR II® is an internationally recognised software, widely utilised by EPCs, owner-operators, and notified bodies for its reliability and accuracy.

Comprehensive piping

stress analysis

Offers static, dynamic, and non-linear analysis capabilities to accurately assess piping stresses under various loading conditions.

Compliance with

International Standards

The wide range of supported international codes and standards (including ASME, ISO, EN, B31.1, B31.3) ensures that projects meet specific regulatory and safety requirements.

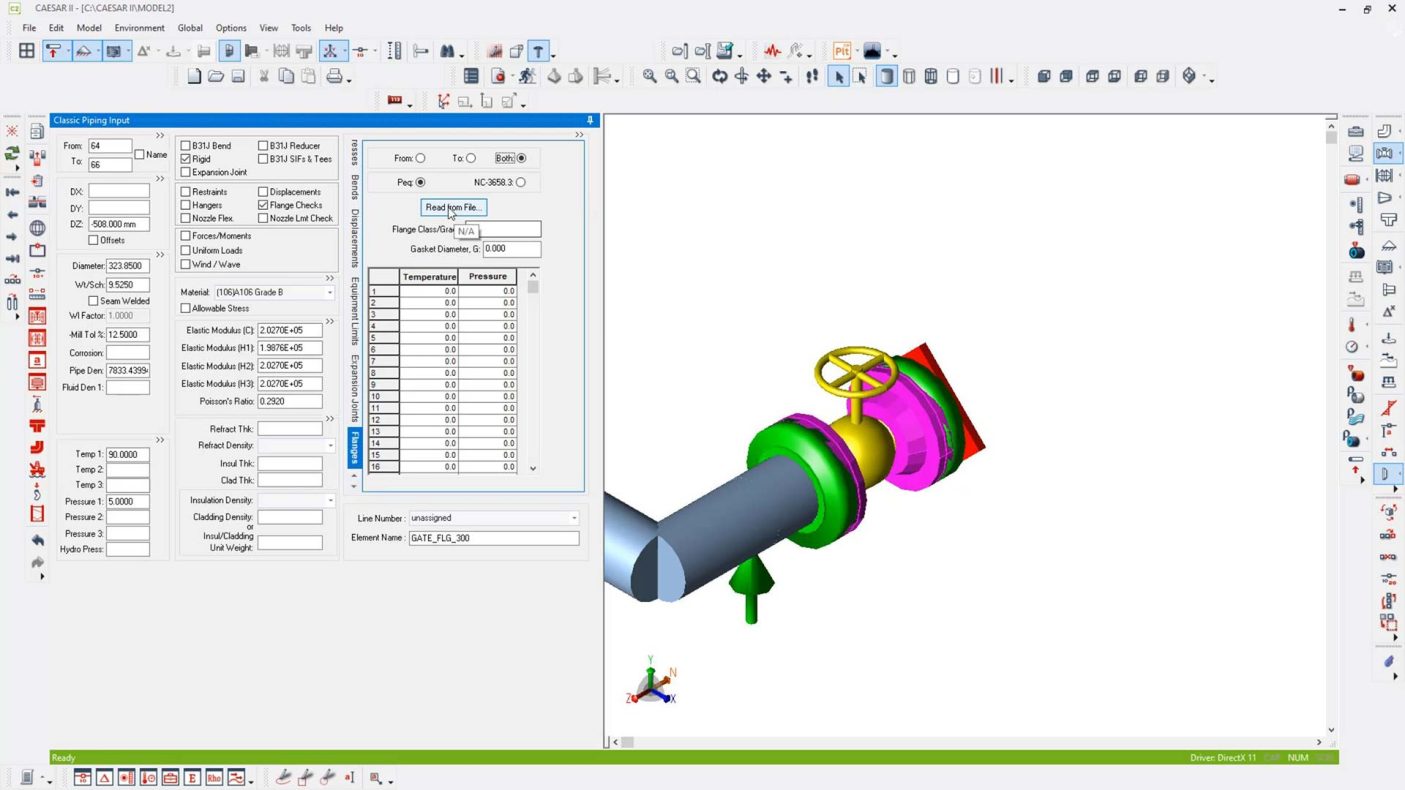

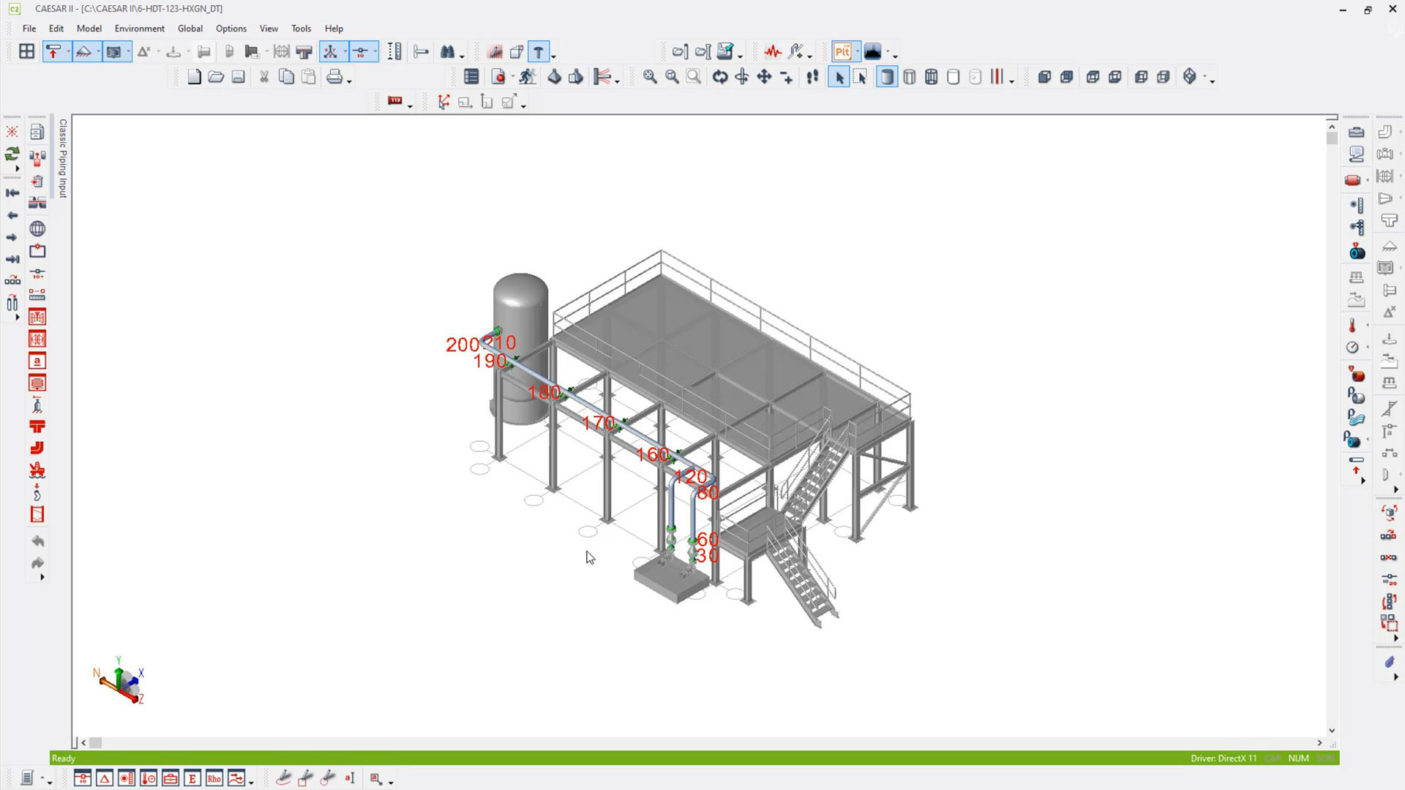

Intuitive user interface

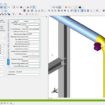

CAESAR II® features a user-friendly interface with graphical input and 3D visualization, improving modeling efficiency and aiding in the early detection of design issues.

Advanced load and support

modeling

Simulates various load types and support conditions with high accuracy, enabling realistic replication of real-world scenarios.

Integration with other

software

Seamlessly integrates with other Hexagon tools and supports data exchange with major CAD and engineering platforms.

Detailed reports

and documentation

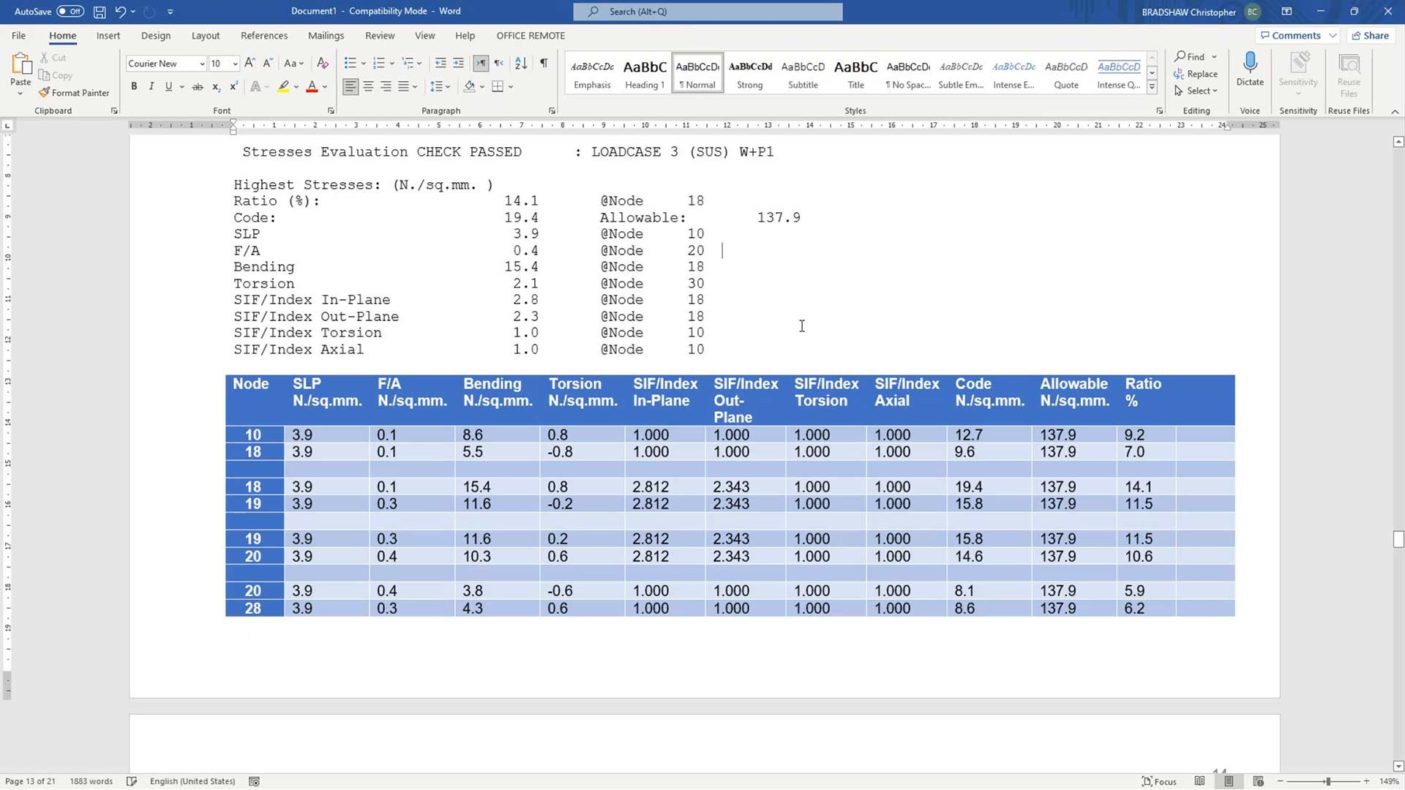

CAESAR II® generates customisable and comprehensive reports of critical data, essential for documentation, review, and compliance verification.

Advanced design

optimization

It optimises piping systems through iterative design analyses considering costs, weight, and performance, and evaluates the impact of vibration impact.

Accurate simulation

of real-world conditions

The software accurately simulates the effects of temperature and pressure on piping systems.

Features

Piping system modelling

Analysing piping systems needs to be fast and absolutely reliable. CAESAR II® offers various features that help analysts develop nodal models quickly and accurately, aiding in meeting project timelines.

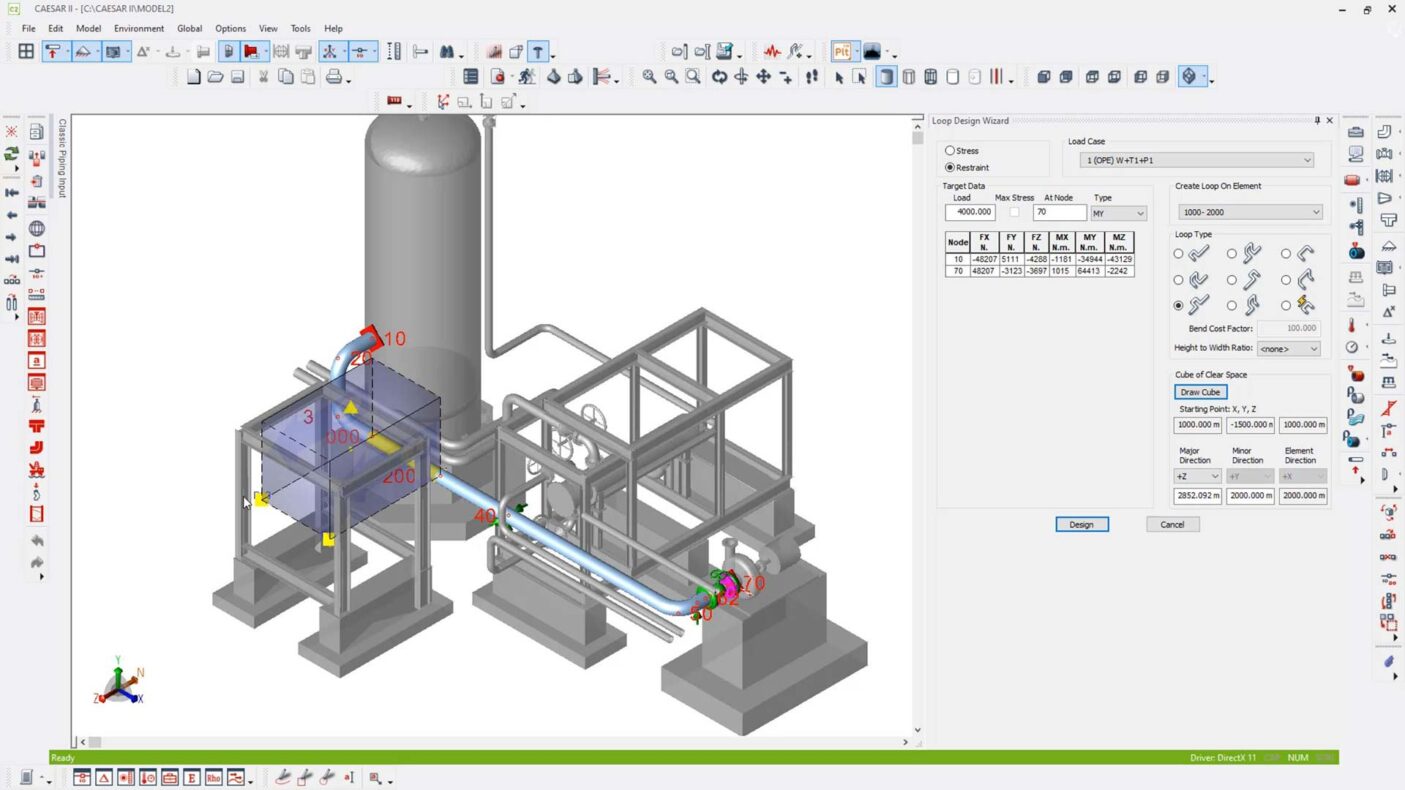

Expansion loop wizard

Adding an expansion loop is a common solution in a piping system. CAESAR II® provides tools to determine the most suitable location for the loop and to calculate the necessary dimensions, reducing the need for repeated analyses and designs.

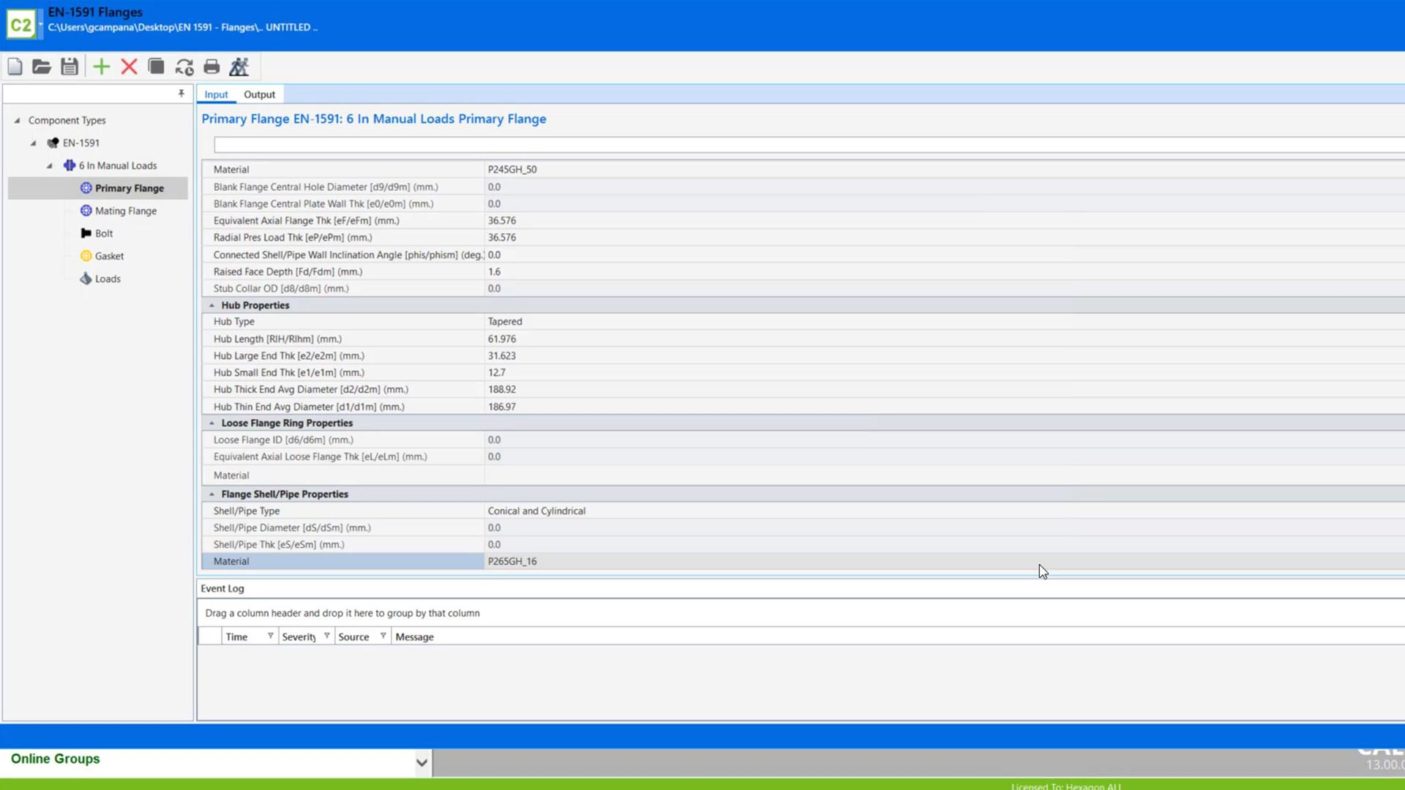

EN1591 Flange Analysis

The EN-1591 standard is a calculation method for circular, bolted, and gasketed flanged joints, ensuring structural integrity and leak tightness. More precise than the Taylor Forge method, it allows for reductions of up to 50% or more in flange thicknesses and bolt sizes.

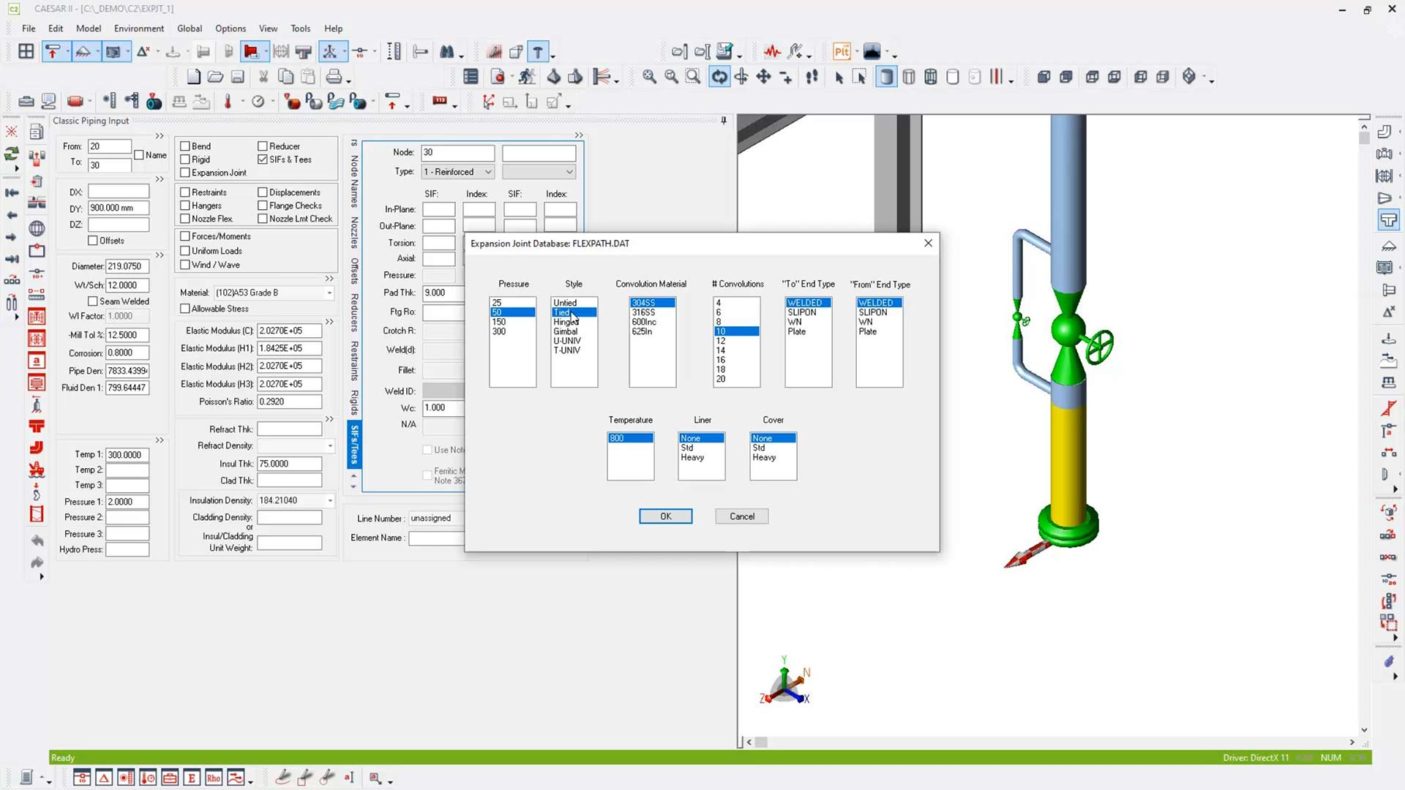

Expansion Joint Wizard

Including an expansion joint in a piping analysis model can be challenging. CAESAR II®’s expansion joint modeller simplifies this process, automatically creating the model with the correct flexibilities and connections – including tie rods.

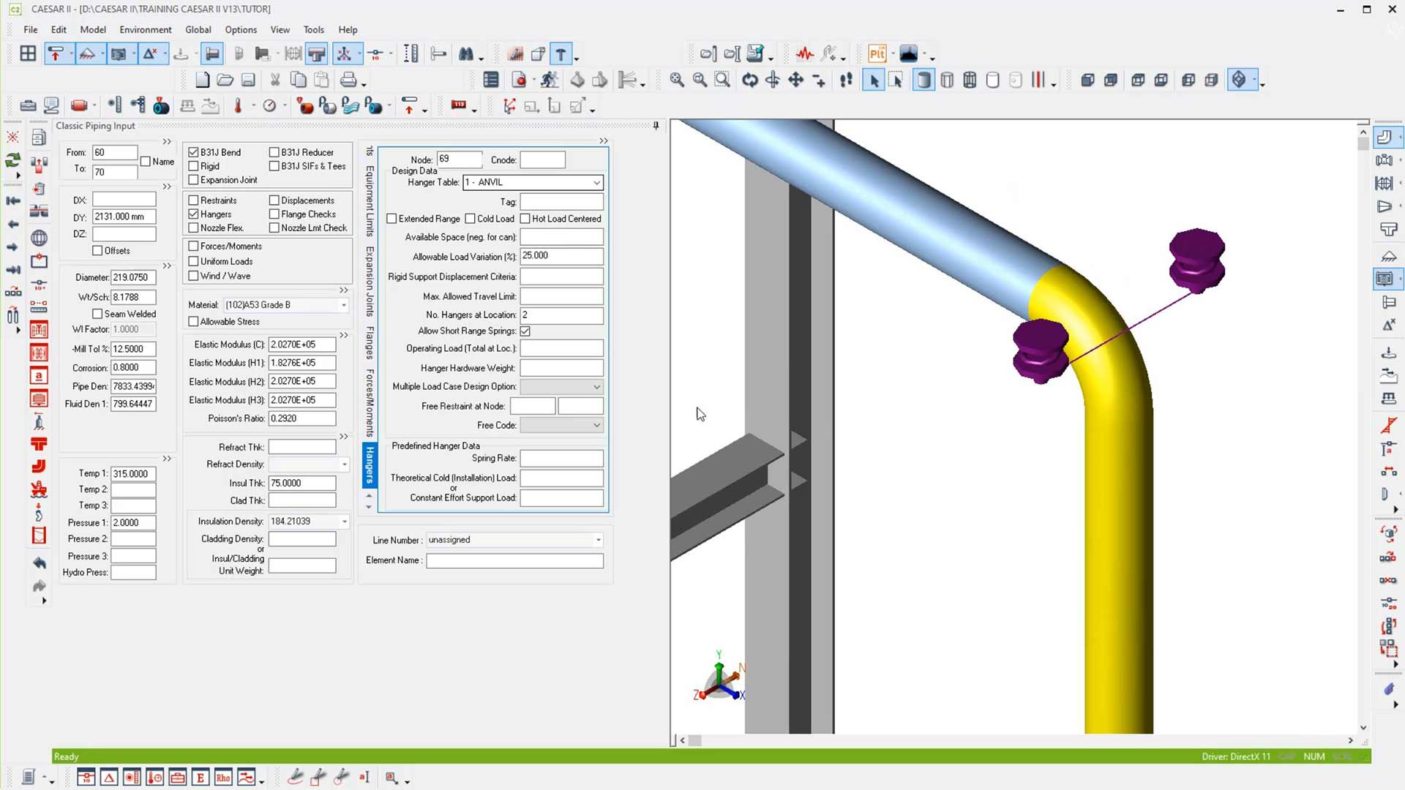

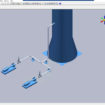

Hanger design and databases

Spring supports are crucial for sustaining a piping system when balancing vertical displacements. CAESAR II® offers users the ability to draw from 38 product catalogs and selects the appropriate support based on user-specified load and movement.

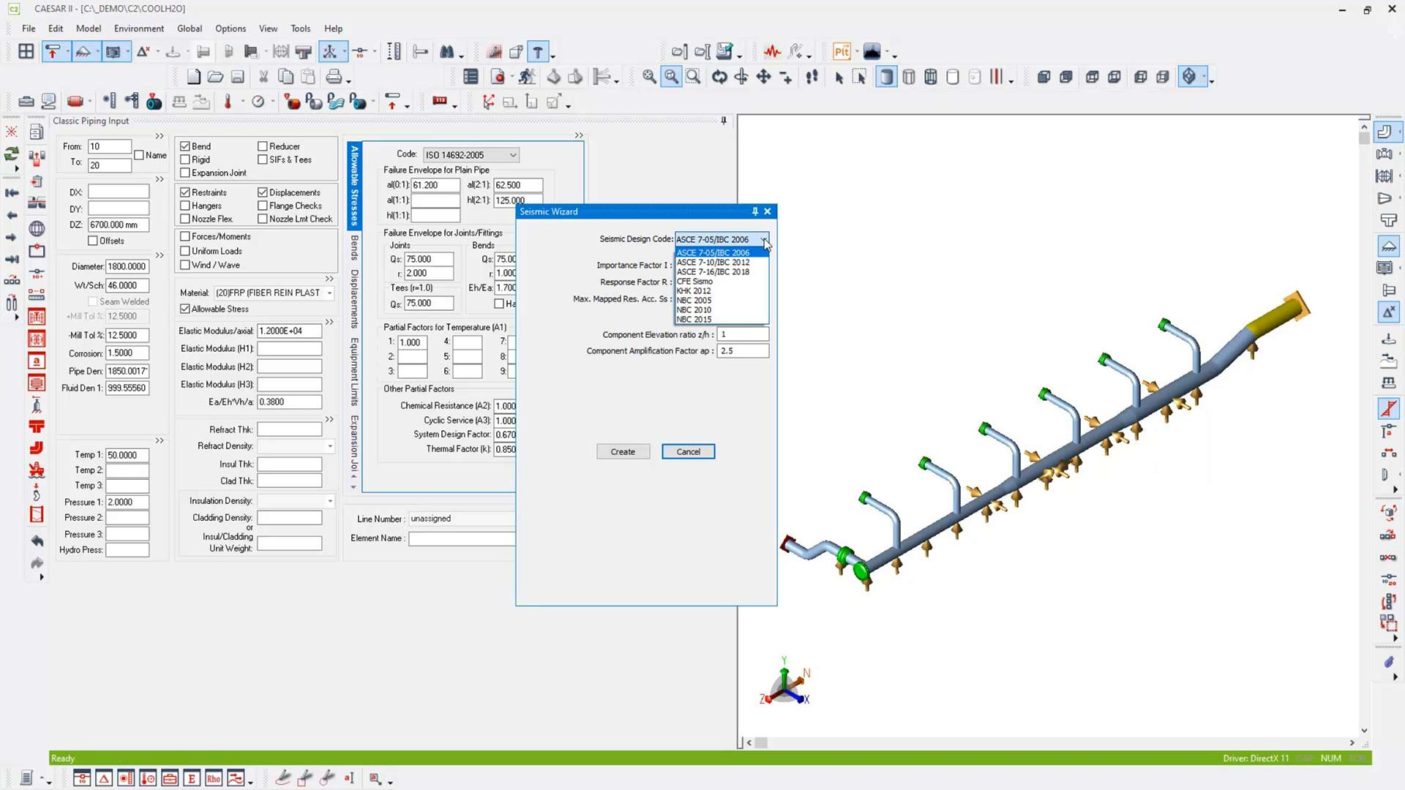

Seismic wizard

Piping systems in earthquake-prone areas must be designed to withstand seismic loads. Fortunately, CAESAR II® allows users to easily apply mapped accelerations to their models with minimal input and in seconds.

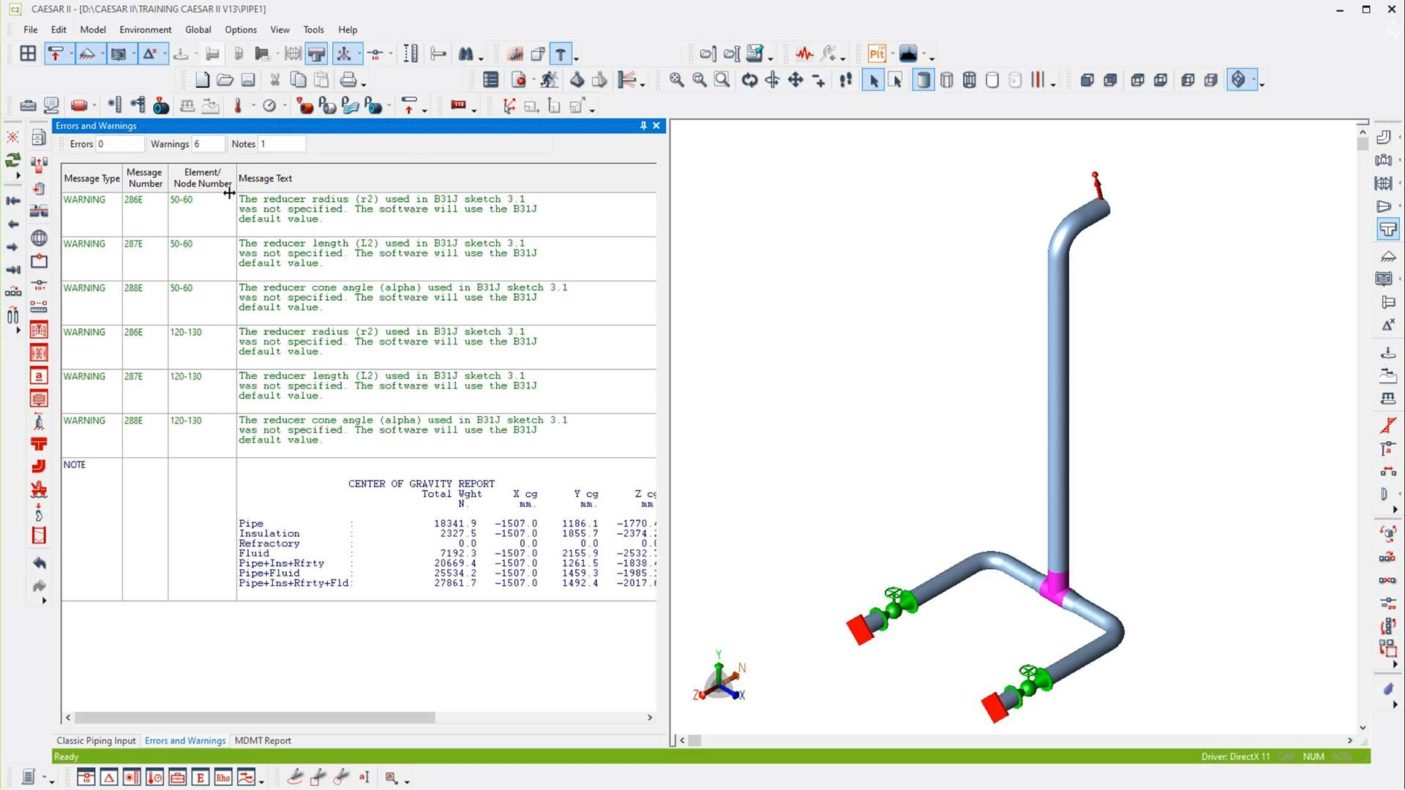

Comprehensive error checking

CAESAR II® includes a comprehensive error checker, refined over many years. This feature verifies user input and provides assistance if something unexpected or undefined is identified in the input.

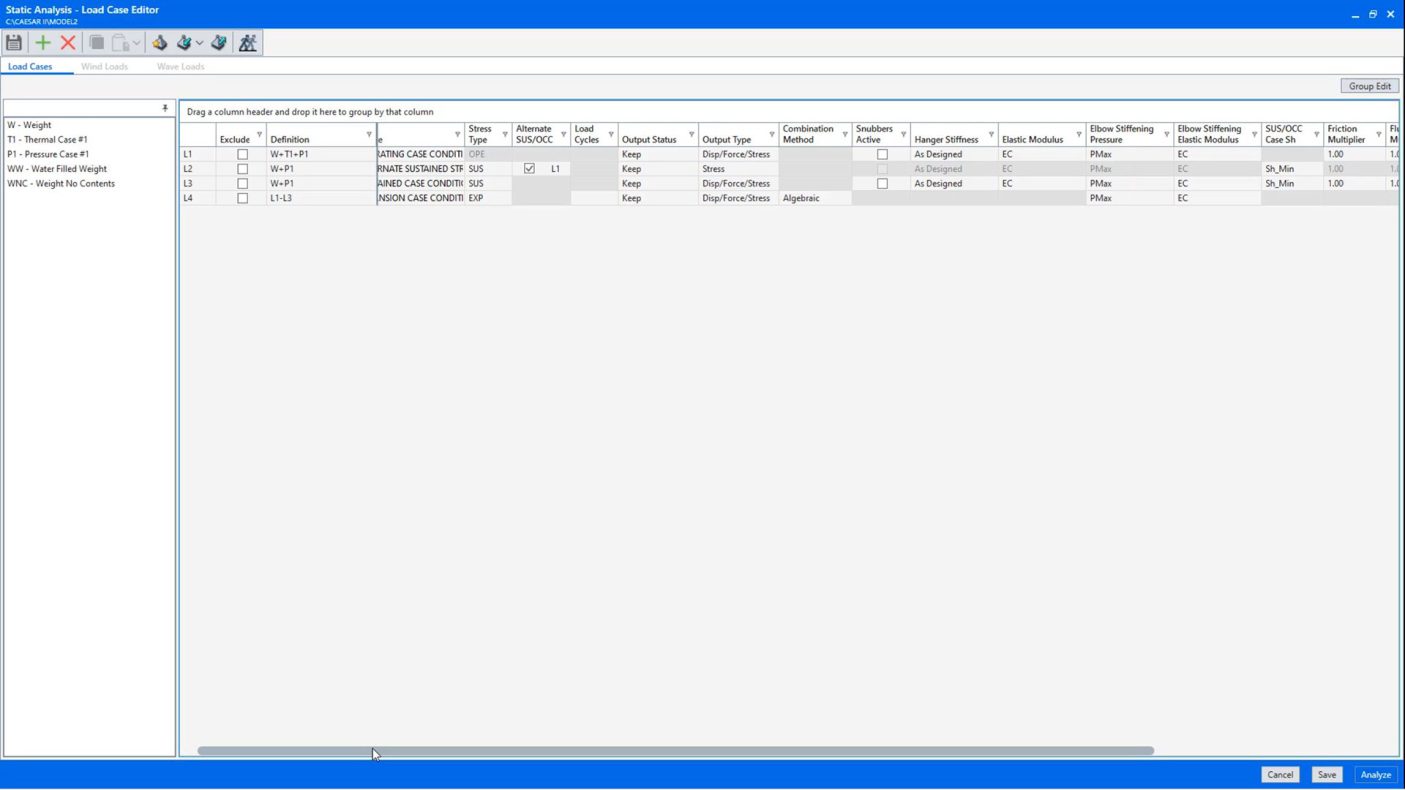

Load case editor

Specifying all applicable load cases for the design scenario is a critical part of the analysis process. CAESAR II® saves time, as the software suggests load cases to use; furthermore, it simplifies working with complex load cases.

Report generation

After completing the analysis, it is often necessary to share the results with other stakeholders. CAESAR II® allows users to easily export analysis results in common formats such as MS Word or Excel.

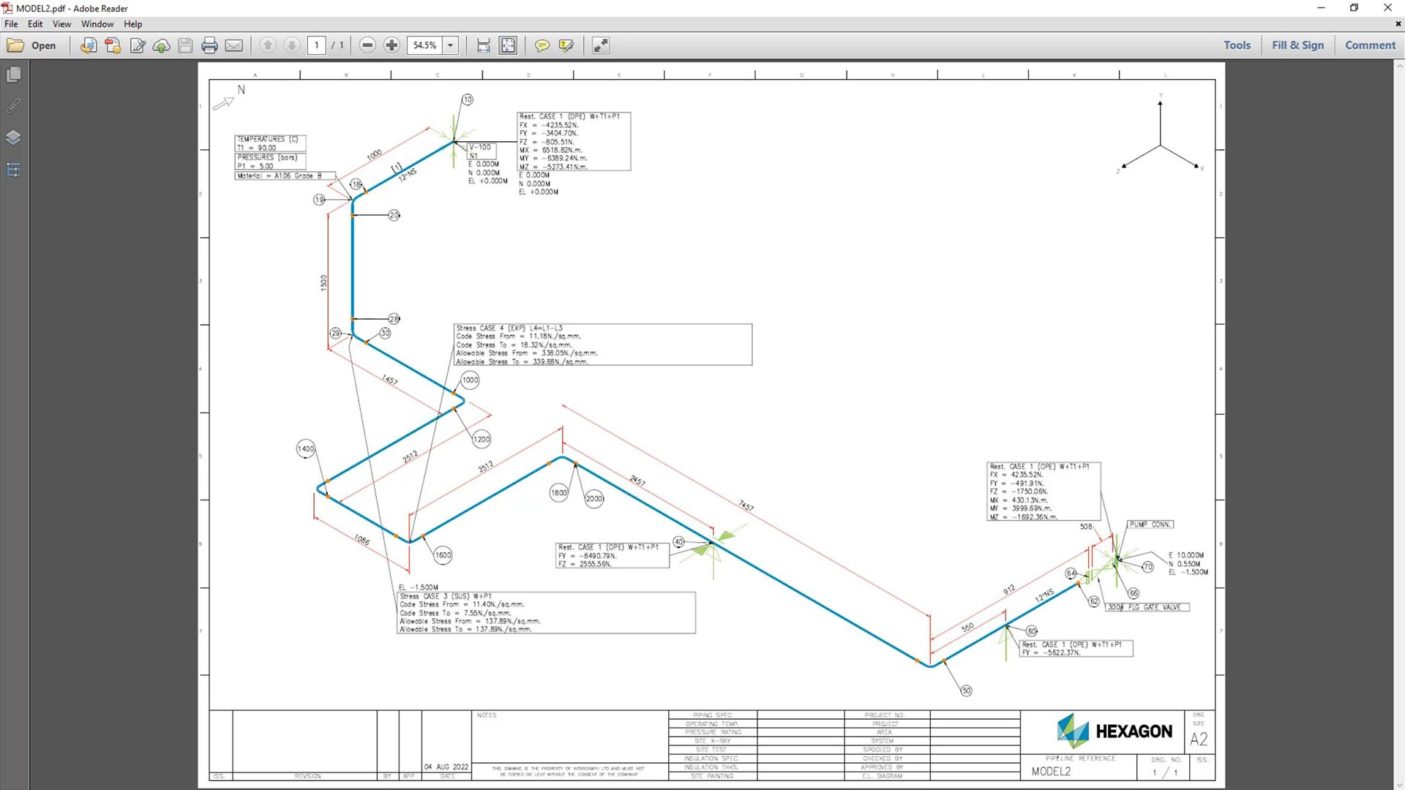

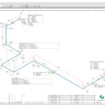

Stress isometrics

A stress isometric is a useful addition to any report. Annotating it manually, however, is time-consuming and prone to errors. With Isogen, an integral part of CAESAR II®, you can produce accurate isometric drawings quickly and with a few clicks.

Piping analysis integration with CADWorx® Plant Professional

The process of creating a piping stress analysis model can be quite time-consuming. CADWorx® and CAESAR II® can streamline this process by digitally transferring piping data from the design model to create the analysis model.

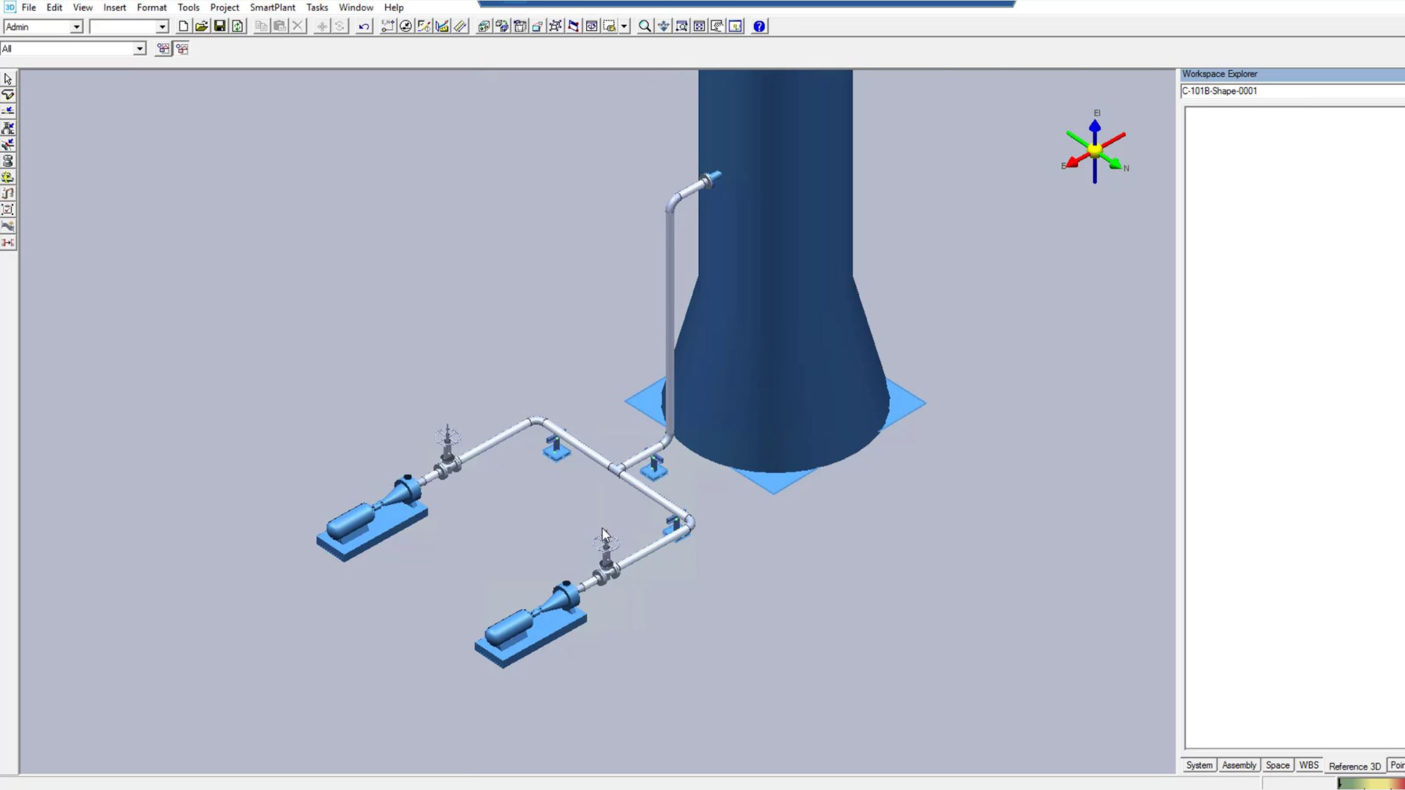

Piping analysis integration with Smart 3D

Often the most challenging part of stress analysis is the (manual) creation of the model from isometrics. The process can be simplified by digitally transferring data from the design model in Smart® 3D to CAESAR II® to directly create the analysis model.

Capabilities

- Static and dynamic analysis

- Intuitive model creation

- Design tools

- Plant model visualization

- Comprehensive error checking

- Customizable reports

- Wind and wave load evaluation

- Seismic and support settlement checks

- Extensive material and expansion joint libraries

- Full support for international piping codes