PIPESTRESS®

PIPESTRESS® is advanced software for analyzing and simulating piping systems under various loading conditions. It is widely used in sectors such as oil & gas, power generation, and industrial plant design to ensure the integrity and safety of piping networks.

Continuously updated in line with international quality standards, PIPESTRESS® is currently used in over 50 nuclear power plants worldwide for piping stress analysis.

PIPESTRESS® enables linear elastic analysis of three-dimensional piping systems under a wide range of loading conditions, as well as the simulation of basic non-linear behavior in one-dimensional pipe supports. This allows for accurate evaluation of piping systems used in chemical processes, as well as nuclear and conventional power generation, to verify compliance with applicable codes and operational constraints.

PIPESTRESS® is the go-to solution for mechanical engineers performing static and dynamic piping stress analysis.

- Oil & Gas

- Chemical Industry

- Mining

- Power Generation (Nuclear, Thermal, Renewable)

- Heavy Industrial Plant Construction

- Heavy Infrastructure Construction

Benefits

Renowned software

PIPESTRESS® is internationally recognized as a leading solution for nuclear projects, widely adopted by EPCs, owner-operators, and regulatory bodies.

Comprehensive stress analysis

Provides both static and dynamic analysis capabilities to evaluate piping systems under a variety of load conditions, including pressure, temperature, seismic, and wind.

Compliance with international

codes and standards

Supports a broad range of global standards, ensuring regulatory compliance including ASME B31.1, B31.3, B31.4, B31.8, and EN 13480.

Advanced modeling

capabilities

Enables the creation of detailed 3D models of complex piping systems, with seamless integration into Intergraph Smart® 3D and CADWorx® Plant Professional.

Seismic and vibration

analysis

Includes advanced tools for evaluating seismic activity and analyzing the effects of vibration on piping integrity.

Fitness-for-service

assessment

Allows engineers to assess the remaining life of existing piping systems and make informed decisions regarding maintenance, repair, or replacement.

Safety and risk

mitigation

Equipped with failure analysis tools to identify potential failure modes and support the design of preventive solutions to minimize risk.

Enhanced reporting

and documentation

Generates detailed, customizable reports and provides full documentation of the analysis and design process.

Scalability and flexibility

Offers flexible, scalable licensing options suitable for projects of all sizes—from small installations to large-scale infrastructure.

Features

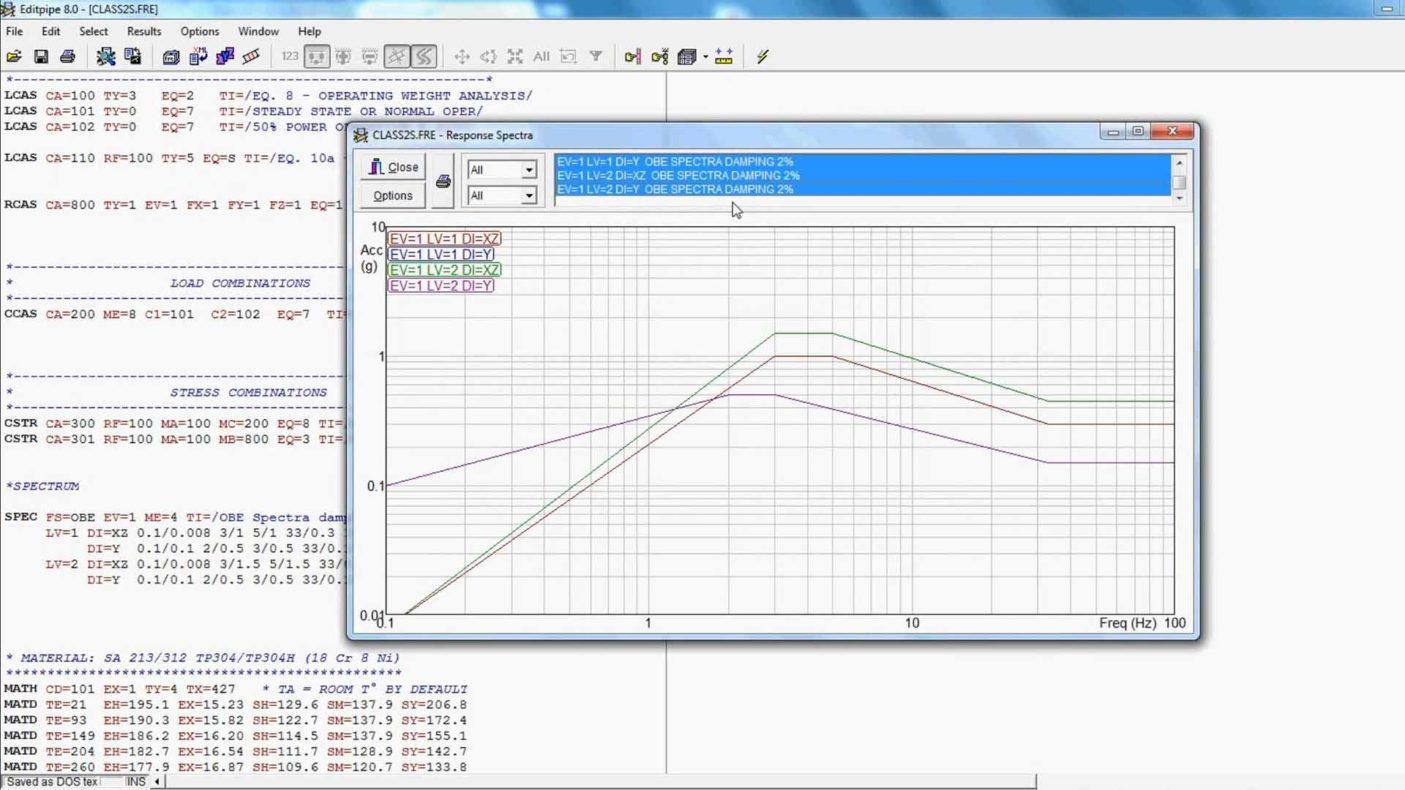

Floor response spectrum analysis

In seismic regions, piping design requires simulating the effects of earthquakes. PIPESTRESS® offers this capability by providing floor response spectrum analysis to visualize system responses across structural levels.

Time history analysis

The dynamic behavior of piping systems can be evaluated through PIPESTRESS®’s time history analysis. This enables informed decisions on how to manage system responses when excited by natural frequencies or other external forces.

Capabilities

- Linear and non-linear calculations

- Up to 500 user-defined load and combination cases

- Heat transfer and thermal gradient stress

- Fatigue analysis (usage factor)

- Thermal stratification

- Mixed classes (different piping codes or standards within the same model)

- Response spectra in cartesian or cylindrical coordinates

- Modal superposition for grouping, double sum, CQC, and other methods

- Time history analysis

- Exceptionally large structures with no topological limitations

- Erosion and corrosion

- Buried piping (soil resistance modeled as soil springs)