PV Elite®

PV Elite® is a comprehensive software application for designing, analyzing, and evaluating pressure vessels and heat exchangers. It is widely used in the chemical, oil & gas, and power generation industries to ensure the safety, reliability, and code compliance of pressure equipment.

Its user-friendly interface makes it ideal even for less experienced users who need a fast and dependable tool for safety code calculations.

PV Elite® performs accurate calculations for the safe design of pressure vessels and heat exchangers, in accordance with internationally recognized standards.

PV Elite® is used by EPC contractors, OEMs of pressure vessels and heat exchangers, asset owners (to assess remaining service life), and notified bodies responsible for calculation approval and commissioning.

- Oil & gas

- Chemical industry

- Power generation (nuclear, thermal, renewable)

- Heavy industrial plant construction

- Heavy infrastructure construction

- Machinery and heavy equipment

- Utilities and communications

- Engineering services

Benefits

Renowned software

PV Elite® is internationally recognized and widely used by EPCs, owner-operators, and certifying bodies for its accuracy and reliability.

Comprehensive code

compliance

Supports a wide range of international codes and standards to ensure project compliance with global regulations.

User-friendly interface

An intuitive graphical interface simplifies navigation and streamlines both design and analysis processes.

Detailed analysis

and simulations

Includes FEA tools for evaluating loads, stresses, and material behavior across pressure equipment.

Efficiency and productivity

Automates complex calculations and allows design reuse, improving consistency and speeding up development.

Enhanced reporting

and documentation

Generates detailed, customizable reports and complete documentation of the design and verification process.

Integration with other

software

Seamlessly integrates with CADWorx® and Smart® 3D for efficient workflows and smooth data exchange.

Risk mitigation

Supports failure risk assessment and ensures compliance with stringent safety and design standards.

Global reach and industry

adoption

Adopted by companies worldwide and established as a standard solution for vessel and exchanger design.

Features

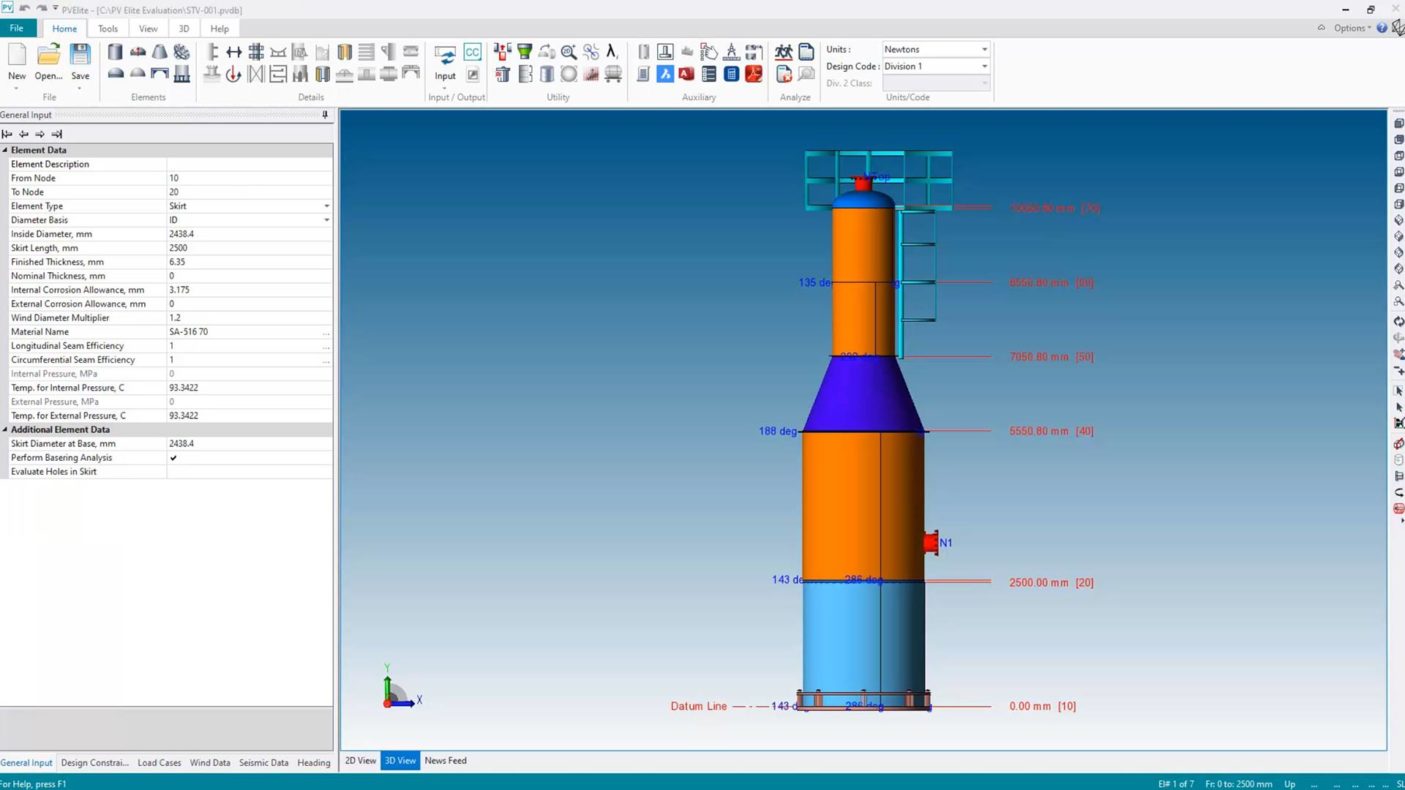

Modeling pressure vessels

Enables fast and accurate modeling of pressure vessels, aligned with all major design codes.

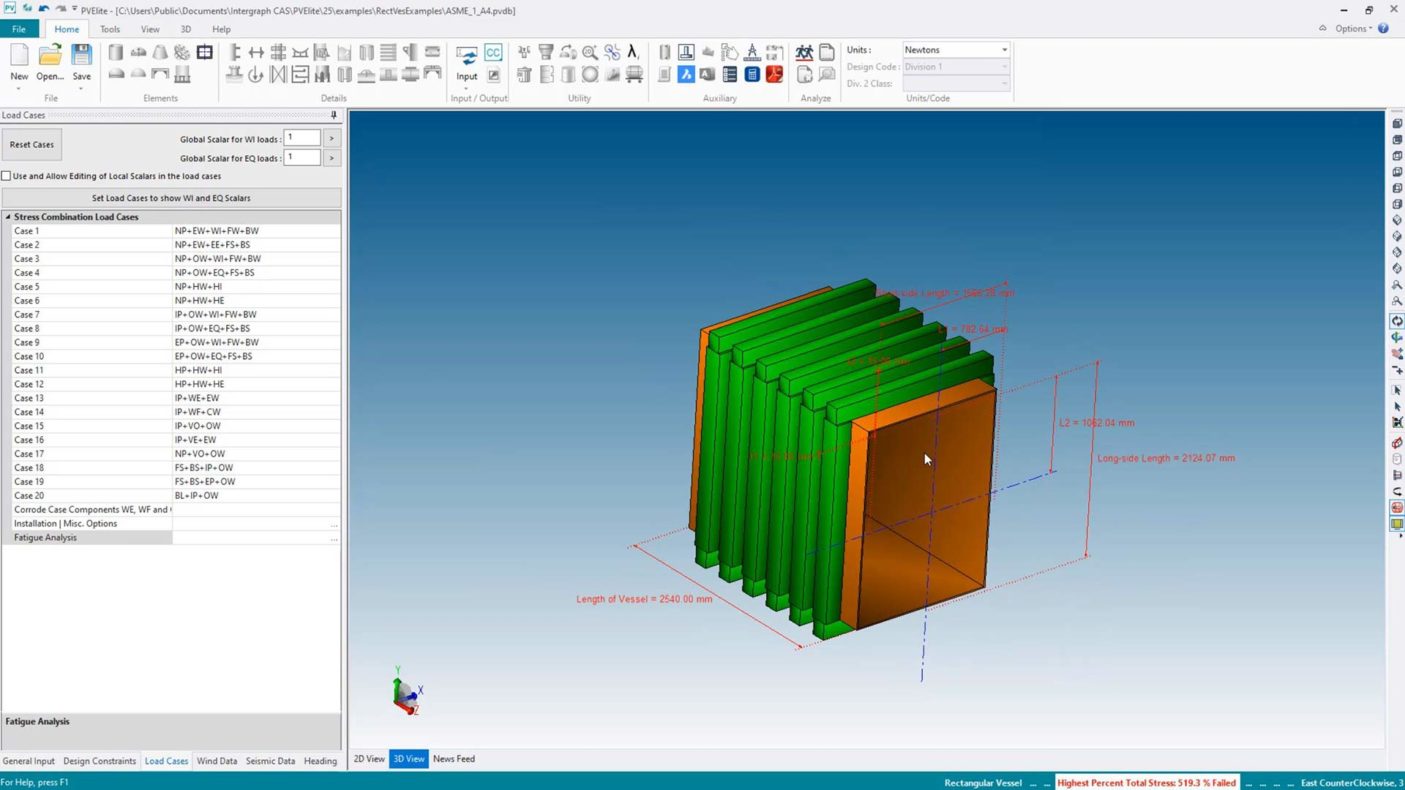

Rectangular vessels

Supports modeling and analysis of rectangular/non-circular vessels according to ASME VIII Div 1 Appendix 13 and EN 13445-3 Section 15.

Nozzle loads on supports

Automatically calculates nozzle load effects on support structures per EN 13445.

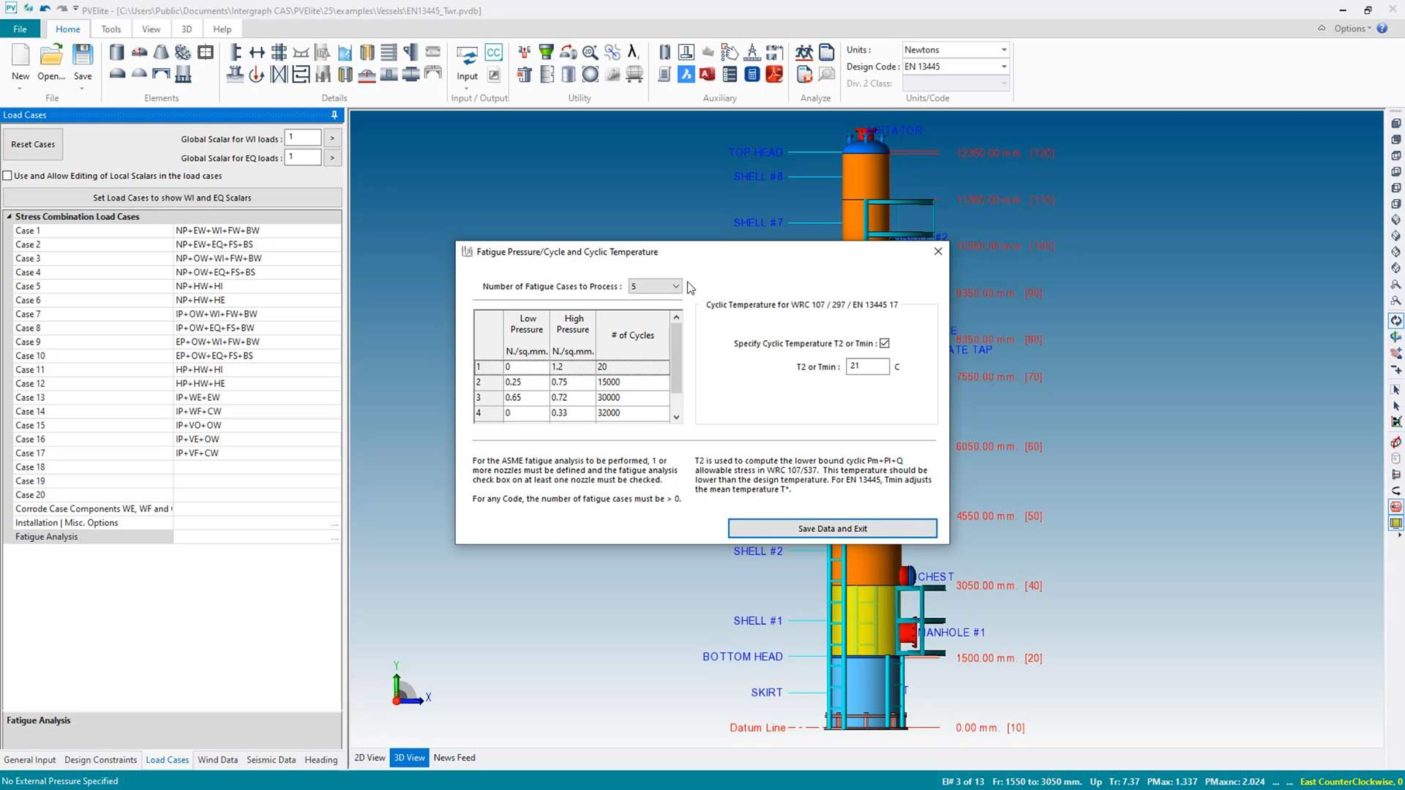

Fatigue analysis

Performs fatigue calculations on nozzles, shells, and heads using simplified assessments per EN 13445-3 Section 17.

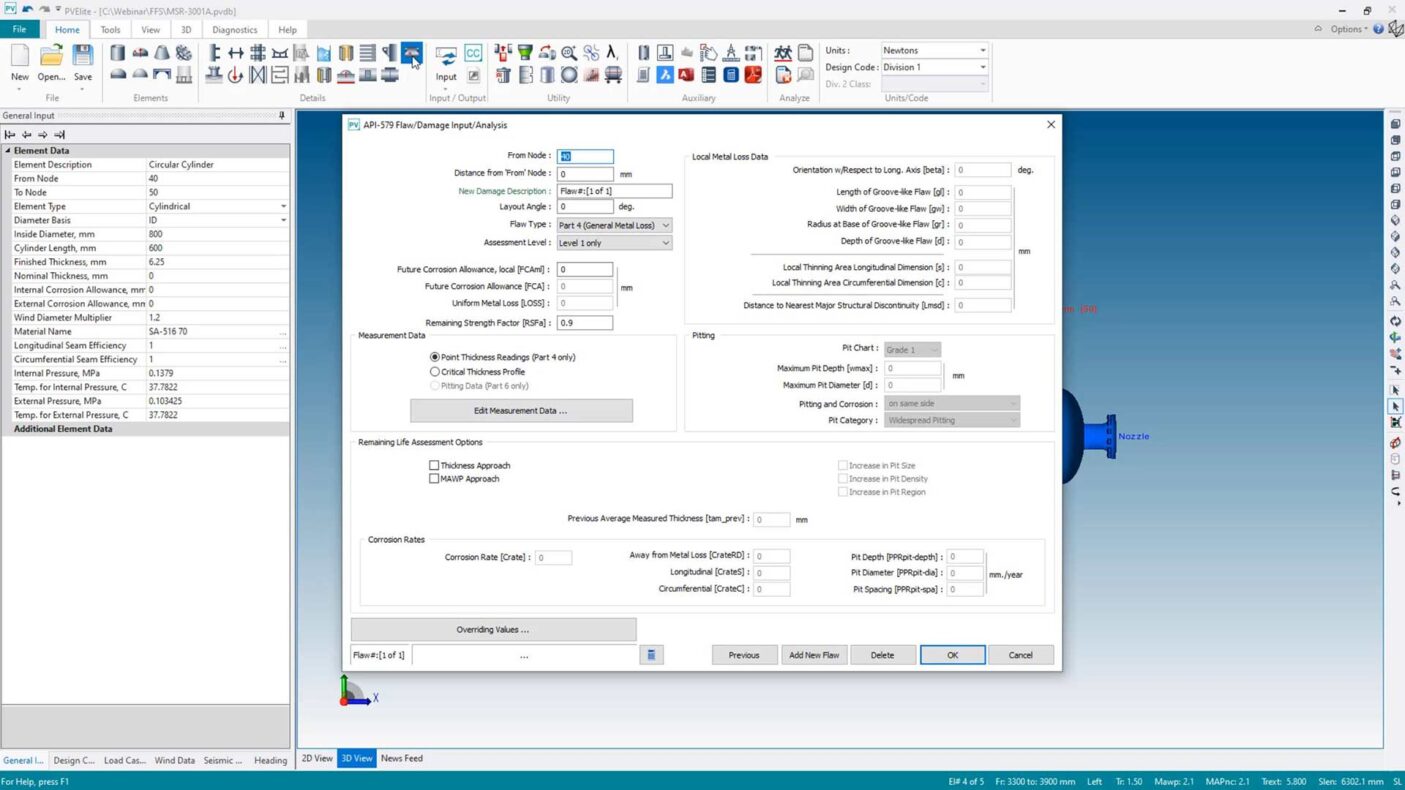

Fitness-for-service

Per API-579, evaluates vessels with identified defects to determine continued operational safety.

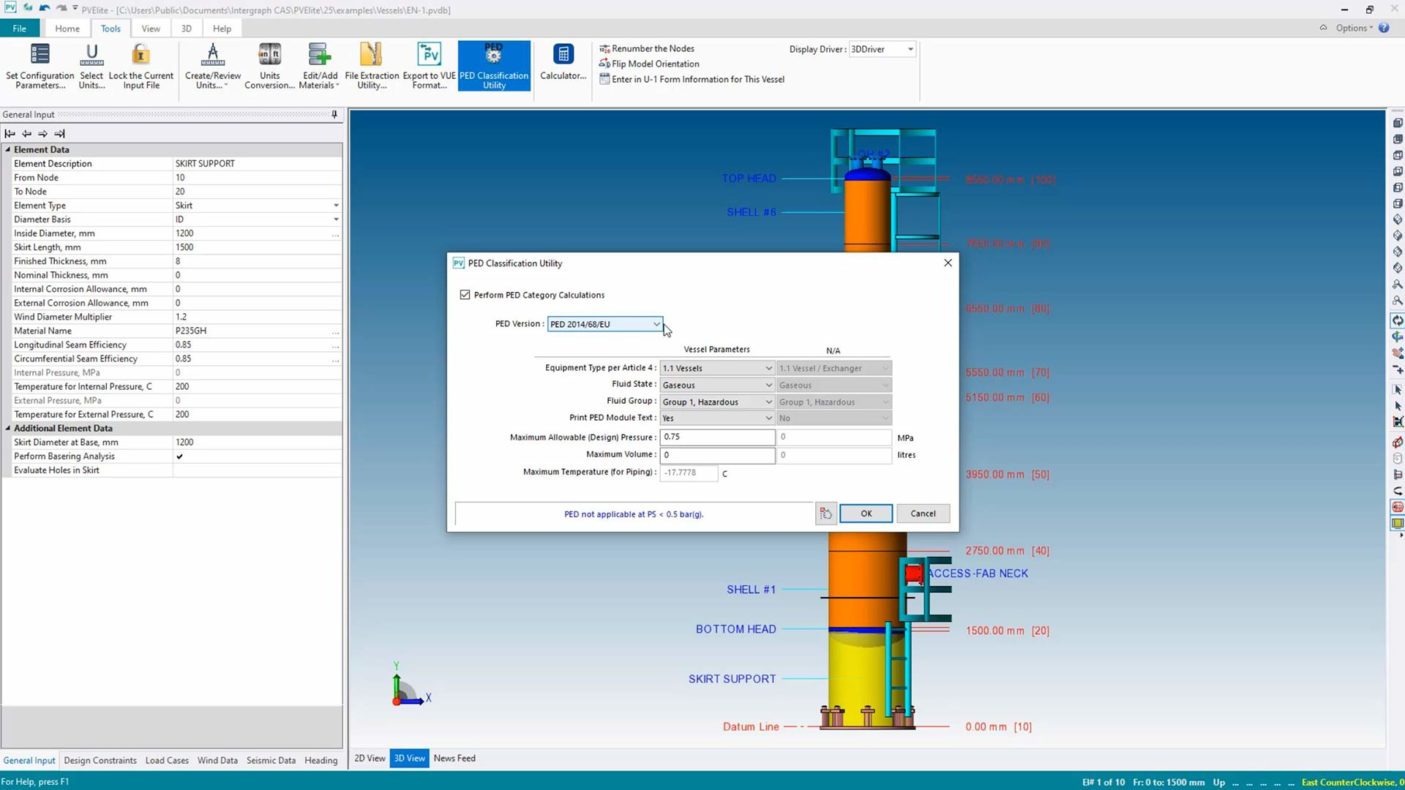

PED classification

Assesses pressure vessels and heat exchangers for compliance with the Pressure Equipment Directive and generates corresponding reports.

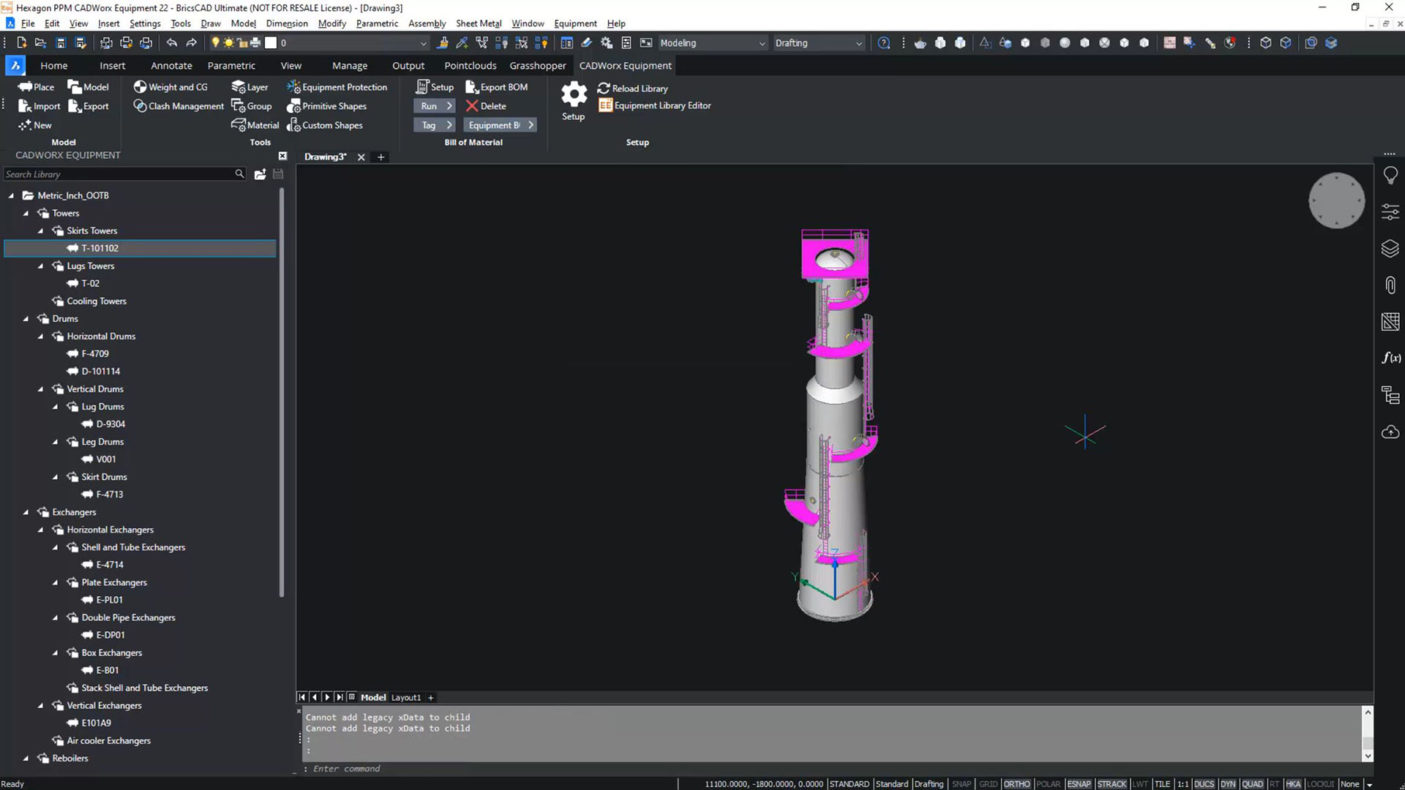

Integration with CADWorx® Equipment

Synchronizes design and analysis workflows to reduce rework and improve efficiency.

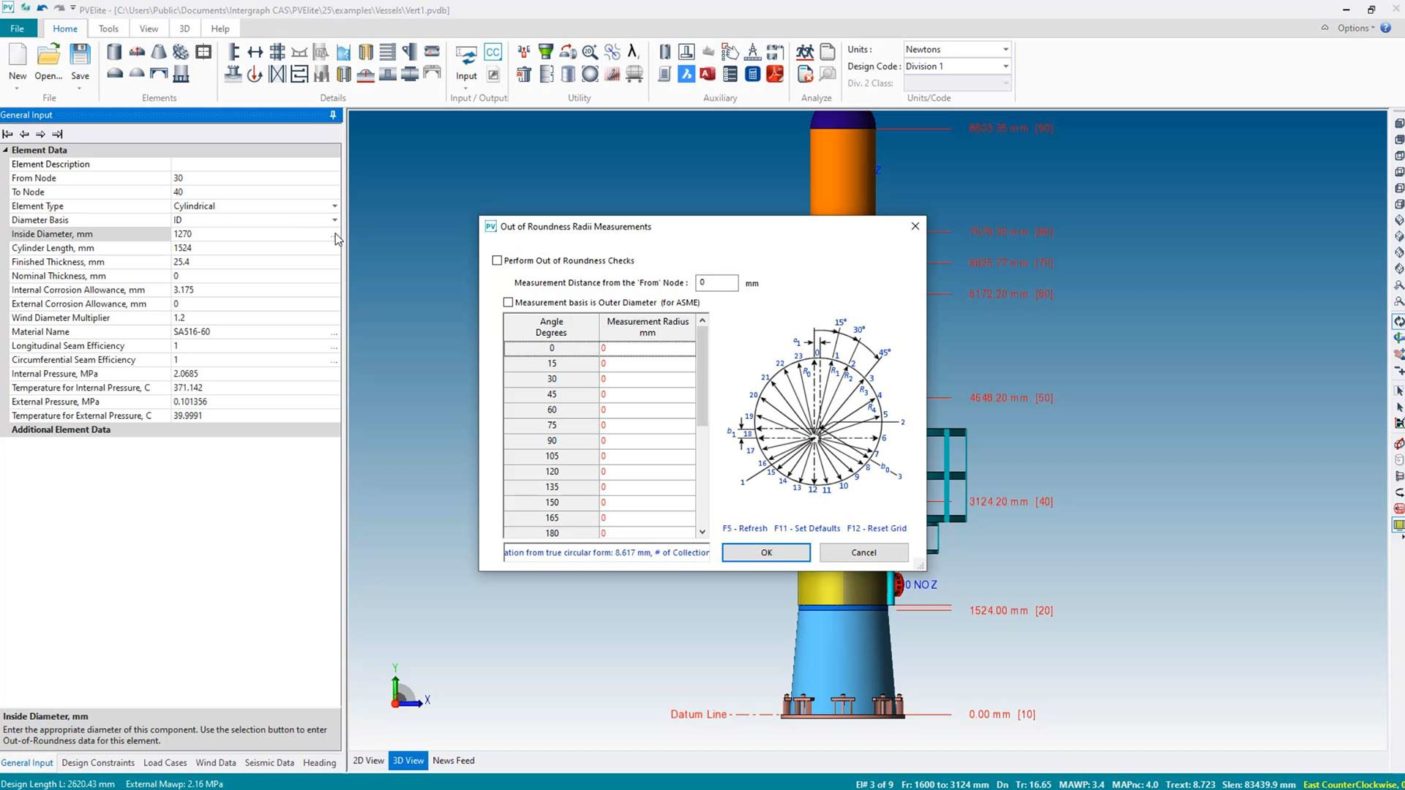

Out-of-roundness

Performs ovality checks based on ASME, EN 13445, and PD5500 standards using as-built measurement input.

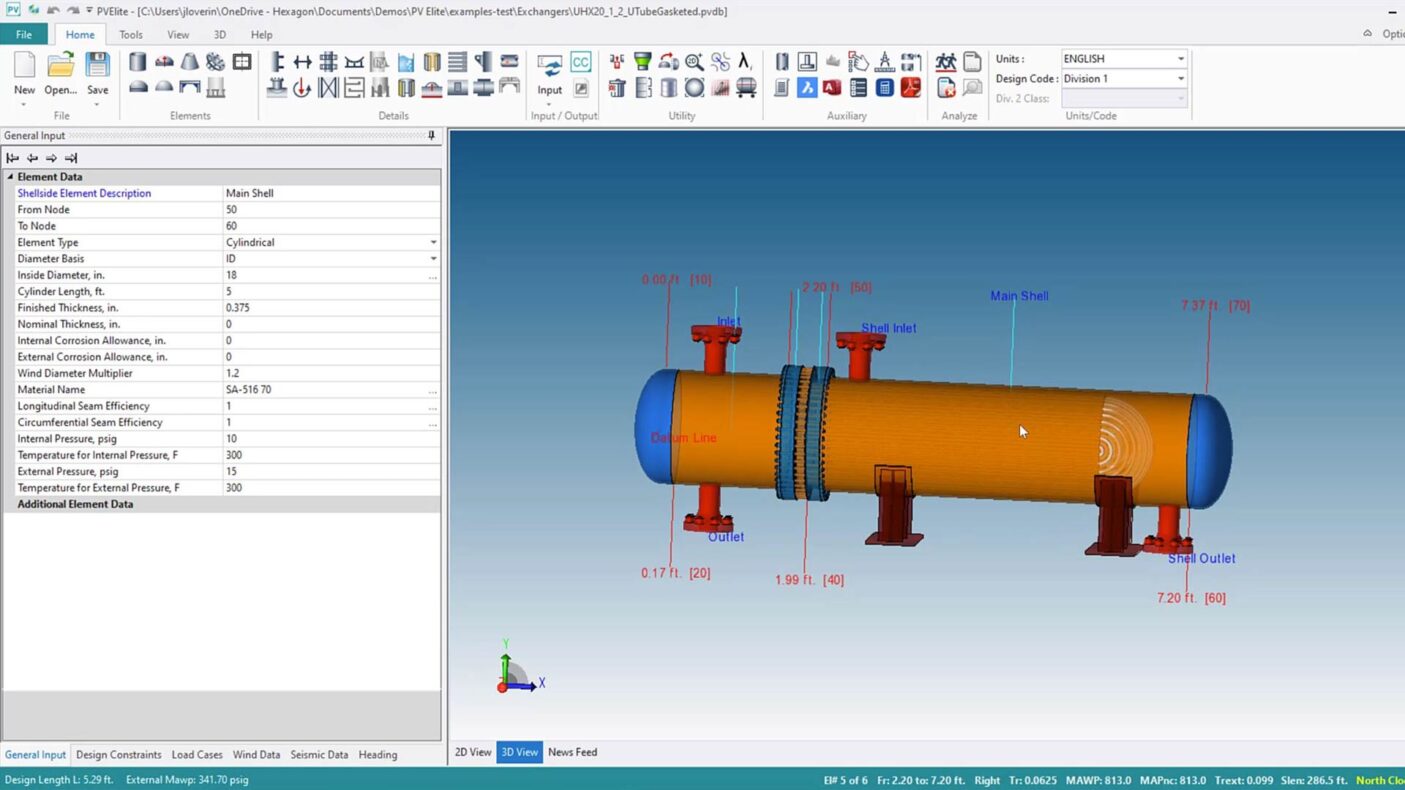

Heat exchanger design and analysis

Supports TEMA, ASME UHX, EN 13445, and PD5500 standards, with automated tools like tube layout assistance.

Capabilities

- Vessel design and analysis

- Exchanger and tubesheet design

- Rectangular and non-circular vessel analysis

- Individual component analysis

- Comprehensive error checking

- Customizable reports

- International wind and seismic analysis

- International vessel codes

- Bi-directional integration with CADWorx® Plant Professional

- 3D PDF generation