Analysis Engineering

and stress analysis

for structural reliability

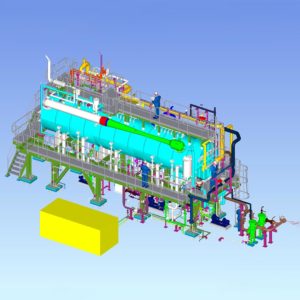

3Units provides comprehensive analysis engineering services to prevent structural issues — from stress analysis to FEM simulations — for plants and structures of any complexity.

Our proven experience in the field allows us to accurately assess the stress state of materials and structures. This enables us to anticipate potential failures and ensure the long-term safety and reliability of industrial systems.

ANALYSIS

Stress Analysis

and Support Sizing

Stress analysis is an engineering discipline focused on evaluating the stress state of materials and structures subjected to static or dynamic loads. With over twenty years of experience in this field, 3Units performs advanced stress evaluations across a wide range of industrial plants — including power, chemical, and oil & gas facilities.

Our expertise enables us to address multiple aspects of design, including structural verifications on existing plants in the event of failures or instability, as well as accurate support sizing. We use industry-standard software such as CAESAR II and PIPESTRESS to perform precise analyses and ensure full functionality and safety of the systems.

COMPLIANCE

Structural Verifications and FEM Analysis of Plants

Structural analysis determines the distribution of internal forces, moments, stresses, deformations, and displacements within a structure or its components.

Our services include:

- Structural verifications using the Finite Element Method (FEM)

- Verification of pressure vessels in accordance with European standards, ASME, and API 650

- Plant sizing

- Development of PFDs (Process Flow Diagrams) and P&IDs (Piping and Instrumentation Diagrams)

- Preparation of component data sheets, operational manuals, and piping layouts

All our structural verification and FEM analysis activities are carried out with a strong focus on regulatory compliance and plant safety.

RELIABILITY

Efficiency Control of Pipes and Supports

Among our specialized services is the efficiency control of piping systems and supports — a critical activity to ensure plant safety and long-term reliability. Using a proven methodology, we reduce pipe stress and help restore the system to optimal design conditions.

Our intervention includes:

- Verifying the main loads on pipes and supports to identify high-stress areas in critical lines

- Proposing corrective solutions to restore piping integrity and address anomalies or defects in support systems

- Performing spring hanger balancing to ensure proper load distribution

CALIBRATION

Pressure Vessel Sizing

3Units provides pressure vessel sizing services in full compliance with ASME, EN, and PD5500 standards. We use specialized software to ensure maximum accuracy when evaluating key components such as heads, cylindrical shells, and conical transitions.

Our services also include:

- Verification of operational stability and evaluation of occasional loads, including wind and seismic forces

- Nozzle sizing and definition of allowable loads according to WRC, EN, or PD5500

- Sizing of non-pressure components upon request

SUPERVISION

Computational Fluid Dynamics (CFD)

Computational Fluid Dynamics (CFD) is a fundamental tool for optimizing design. At 3Units, we use CFD to perform advanced analyses of heat transfer and thermal comfort, enabling both cost savings and qualitative improvements for our clients.

CFD has a wide range of applications. Through detailed simulations, we design closed ventilation systems that ensure maximum comfort and reduce fire risk in buildings and complex infrastructures such as tunnels, railway stations, airports, and industrial facilities. By integrating CFD into the design process, we help optimize your projects for a safer, more efficient, and sustainable future.

Discover our case studies

Tavazzano e Montanaso

3Units contributed to the Tavazzano and Montanaso power plant upgrade with advanced 3D modelling, automated workflows and high-precision engineering of 2,500 mechanical supports.

Read the latest news