Predictive maintenance of a chemical plant: from laser scanning to Digital Twin

INTRODUCTION

Today, the digitization of industrial plants is no longer optional — it is a strategic necessity for companies that aim to stay competitive.

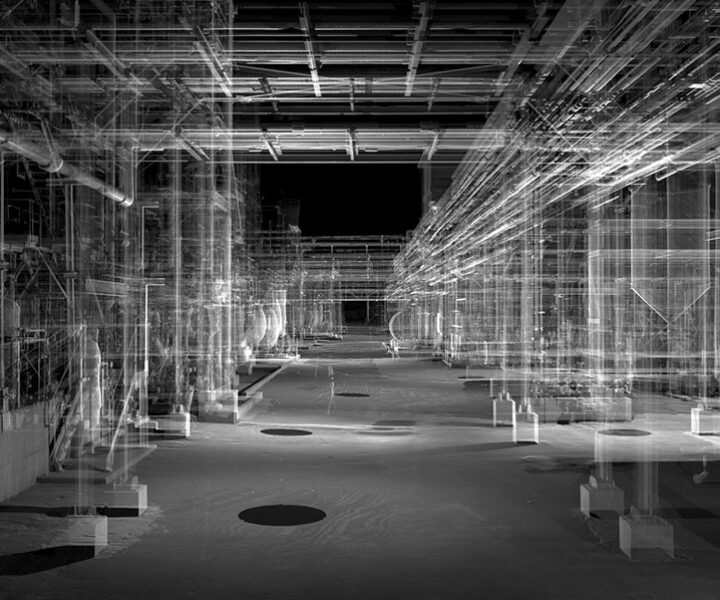

With this in mind, 3Units, in collaboration with WeScan, undertook an ambitious project for HYDROCHEM, part of the Altair Chemical Group, a company specializing in the design and construction of chemical production facilities. Our team traveled to the province of Verbania to create a highly accurate and up-to-date digital representation of a 160,000 m² production site. The goal was to overcome the limitations of existing documentation and establish a solid foundation for efficient predictive maintenance.

The main challenge was to map a vast area with significant structural complexity — all within a tight timeframe and with maximum precision. Thanks to cutting-edge technology and the combined expertise of 3Units and Wescan Solutions, we exceeded the client’s expectations and delivered a high-quality digital model.

STEP 1

Integrated survey

with SLAM technology

To address the complexity of the project, we adopted an integrated survey approach that combined SLAM (Simultaneous Localization and Mapping) technology with traditional topographic methods. This enabled the rapid acquisition of high-density, geo-referenced data.

The first phase involved the installation of a high-precision topographic control network, followed by the placement of reference points to ensure the accuracy of the point cloud. An operator then performed the survey using a mobile laser scanner — a compact, lightweight device equipped with LiDAR sensors and Full HD cameras — allowing for safe and precise data capture throughout the site.

STEP 2

Post-processing and digital

twin creation

Once the survey was completed, the acquired data was processed using specialized software. The coordinates of the control points were integrated to correct the mobile laser scanner’s trajectory, resulting in a highly accurate, consolidated point cloud.

The 3D data was then filtered, cleaned, colorized, and made accessible to the client through a dedicated, user-friendly web platform. This enabled visualization of the point cloud, high-resolution spherical images, and geotagged information related to plant assets. From this dataset, three-dimensional models of piping, equipment, and pipe racks were extracted, forming the basis for the creation of a Digital Twin of the entire industrial plant.

Total area surveyed

Operators involved

Mobile laser scanner

Working days

CONCLUSIONS

Towards advanced predictive maintenance

The creation of a complete and detailed Digital Twin of the chemical plant marked a key step toward predictive maintenance. HYDROCHEM can now monitor asset conditions in real time, anticipate potential failures, and plan targeted maintenance interventions to minimize downtime and reduce operating costs.

This project is a clear example of how digitization can transform industrial maintenance — shifting from a reactive to a proactive and predictive model. With specialized expertise and hands-on experience, 3Units supports companies throughout their digital transformation journey, delivering customized, cutting-edge solutions.