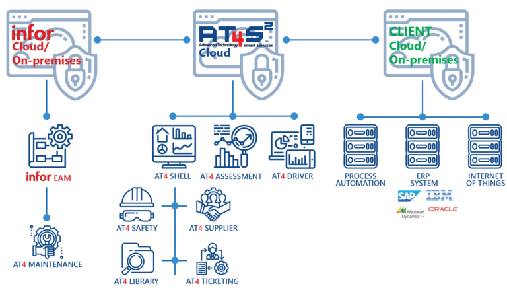

Thanks to digital tools, we support the complete life cycle of production assets and help companies manage their plants as efficiently as possible, aiming to do maintenance only when it is really useful.

Infor EAM

Enterprise asset management

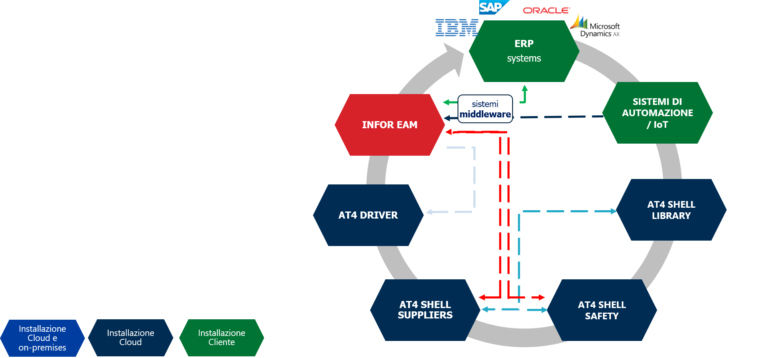

Infor EAM is the top of the Enterprise Asset management software solutions for the management of corporate resources with integrated functionality and flexibility. Integrated with the solutions of the AT4S2 platform, the various ERP systems and technological automation systems, Infor EAM is the basis for the implementation of continuous improvement processes and the implementation of a world-class Maintenance process. Infor EAM manages the entire process of organizing resources: from purchase requests to purchase orders and performance reporting and recording, from spare parts inventory to safety stock management, from the skills of technicians to the skills of suppliers.

AT4 Maintenance

MAINTENANCE is the web app developed ad-hoc by AT4S2 for the complete mobile management of the Infor EAM software processes. The flexibility of use with any mobile device or web browser and the free customization in the use of the customer’s custom fields make AT4 MAINTENANCE an indispensable tool to support the daily activities carried out directly in the field. The main features are:AT4 Driver

AT4 DRIVER is the heart and intelligence of the platform

It is an intelligent dashboard that allows you to monitor each individual asset, technical family, functional hierarchy or cost center in real time:

AT4 Assessment

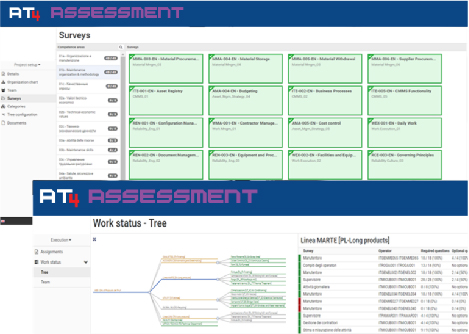

ASSESSMENT is a tool developed to support evaluation processes, managerial and non-managerial, through self-assessment questionnaires with preconfigured checklists.

The configuration of ASSESSMENT is focused on the following main areas:AT4 Shell

Main business processes efficiency in compliance with ISO standards

AT4 Safety

SAFETY is a module included in the SHELL application designed and developed for the complete management of workers’ health and safety and environmental protection in accordance with ISO 45001 and 14001 standards.

AT4 Suppliers

SUPPLIERS is a module included in the SHELL application designed and developed for the complete management of Suppliers, qualification documents and operational management of construction sites. SUPPLIERS allows the total management of the qualification and evaluation process of suppliers, their classification and the management of the documents necessary to perform the various types of services provided. The management of deadlines is completely automated, and the profiling of users and approvals allows a flexible sharing/ distribution of all activities. A portal dedicated to the “reception” allows you to efficiently manage the entry of external staff by checking the adequacy and approval of the required documentation.AT4 Library

LIBRARY is a module included in the AT4 SHELL application designed and developed for complete document management. System features:

AT4 Ticketing

TICKETING is a module that allows the customer a single point of contact (SPOC) for any type of request or communication.

By registering the “Ticket”, AT4 Smart Services undertakes to provide customer support and / or to contact the customer directly for further clarifications. Each ticket entered is taken over by an operator, who activates the specialists for the resolution of the problem highlighted. These activities guide the customer in managing the problem, diagnose and reproduce the problem and, if necessary, activate specialist external services and manage the escalation of the problem itself. Specific indicators of the service level (SLA) determine in real time the respect of the contract times for the various criticalities, the availability of the applications and the status of the hours dedicated to the contractually foreseen improvements (evolutionary maintenance).Integrated solutions

Interconnection with external systems can be implemented through dedicated middleware systems or the interchange of XML/ SOAP flows, through different transport systems (http/ https/ sftp/ …) or through REST calls on http. AT4S2 platform can also collect data directly from the field (through IoT architectures) by communicating with existing sensors or equipment or systems chosen for projects needs and placed on different equipment according to the study problems, simulating and monitoring their operation, either individually and related to other variables of a logical process.

Benefits

…. why choosing us? main benefits for our clients

Process flow tracker

Software solution for the automatic tracking of operating and management processes

Process Flow Tracker is a software solution for the automatic tracking of operating and management processes that is natively supported by automatic data collection (ADC) technologies like Barcode/QRCode, RFID, NFC, BLE. It works with handheld and fixed identification devices and is conceived to allow users to draw their process flow models, achievable by connecting different sequential nodes that represent the real case; through these nodes different entities (raw materials, finished goods, field works) are uniquely identified and traced by properly selected ADC systems. Nodes can be internal or external to the company, without any limitation, and each node will provide the central system with essential data that are important for real-time traceability purpose. What are the benefits?Digilog

Digitization of warehouse operations

The solution allows warehouse personnel to place the materials, from time to time, in different locations, based on current possibilities and needs, and to know where these materials are at any moment, thanks to the use of some identification technologies. automatic, coordinated and integrated with each other. Part of the overall solution is represented by an integrated LED system that guides the workers in identifying the materials they are looking for. What are the benefits?