AutoPipe Piping Design and Analysis Software

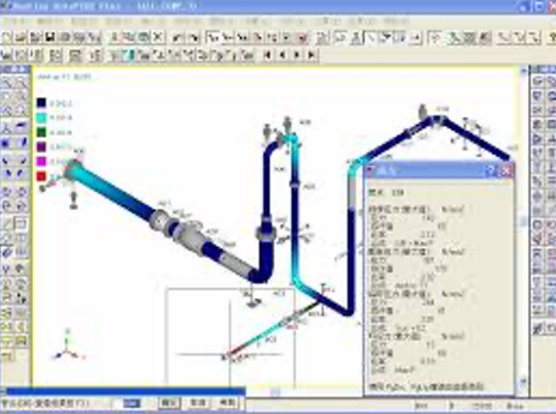

Ensure efficient workflows between pipe stress engineers, structural engineers, and CAD designers through interoperability with leading plant design applications. Speed the design of Class 1, 2, and 3 nuclear piping systems with advanced analysis capabilities such as nonlinear hydrotest analysis, integrated through-wall thermal gradient, built-in fluid transient analysis, thermal bowing or stratification, and seismic response spectra enveloping, for process, power, oil and gas, nuclear, underground, offshore, and subsea pipeline. This nuclear-approved software helps you ensure compliance against design standards including 10CFR Part 50, 10CFR 21, and ASME NQA-1-2008/2009a. Save time and reduce errors with integration to all major intelligent 3D CAD systems, such as OpenPlant, AutoPLANT, PlantSpace, Intergraph PDS and Smart3D, Autodesk Plant3D, and Aveva PDMS. AutoPipe saves you time by enabling you to create, modify, and review piping and structural models and their results quickly and easily. Save even more time by addressing static and dynamic analysis in one application offering advanced linear and non-linear analysis capabilities for temperature, wind, wave, buoyancy, snow, seismic, and transient loadings.

AutoPipe Advanced

AutoPipe Advanced Piping Design and Analysis Software

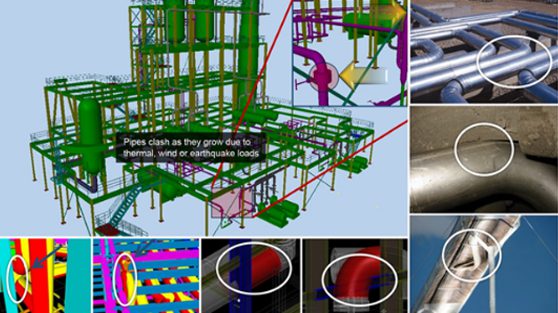

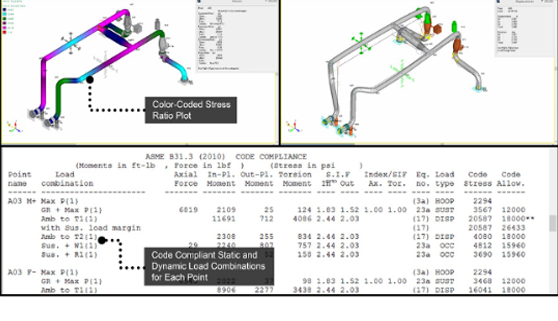

Speed your piping design with AutoPipe Advanced. Increase your productivity and improve quality control with proven, scalable, and integrated pipe stress analysis. Produce compliant designs in less time with integrated stress analysis for a variety of piping environments. Efficiently address a wide range of advanced analysis with a single application that includes built-in wave loading, buried pipeline analysis, jacketed piping, dynamic loadings, orthotropic fiberglass reinforced plastic (FRP/GRP), and HDPE plastic piping analysis. Save time achieving compliant designs with support for all major codes including class 2 and 3. Rapidly create, modify, and review piping and structural models and perform advanced linear and non-linear analysis of static and dynamic conditions. Quickly determine whether or not the wall of a pressure vessel, exchanger, or tank can withstand piping loads. AutoPipe Advanced includes AutoPipe Nozzle functionality, which lets you calculate local stresses at nozzle/vessel junctions, trunnion attachment points, clip connections, and lug attachments. Increase plant model accuracy by determining pipe stress displacements due to loading cases such as temperature, seismic, or other extreme loading conditions. Analyze any loading condition applied to piping and structures then use Navigator or OpenPlant Modeler to evaluate and resolve clashes. Ensure your projects comply with more than 30 global design standards across the power, nuclear, offshore, chemical, and oil and gas industries. Incorporate ASME, British, European, French, Japanese, Russian, API, NEMA, ANSI, ASCE, AISC, UBC, ISO, and WRC guidelines and design limits.

AutoPipe Vessel

Design Software provides you with cost-effective and accurate design of pressure vessels, heat exchangers, tanks, and air coolers. Reduce mistakes and time-consuming manual revisions. Ensure greater efficiency with your supply chain and improved collaboration with engineering companies. Increase your efficiency through fully automatic vessel design optimization under all installation and operating conditions. Increase productivity and provide accurate design for the safe operation of vessels under all loading conditions for pressure vessels, heat exchangers, tanks, and air coolers. Achieve compliance with regional and global standards, including pressure vessel design codes from the past 10 years and regional wind, seismic, wave, and blast-loading codes. Improve flexibility for re-rating and revamping existing vessels. You can design for both brownfield and greenfield projects and shorten design time and rework by eliminating guesswork. Ensure confidence in vessel design and improve your competitiveness through higher design quality. Ensure your projects comply with more than 30 global design standards across the power, nuclear, offshore, chemical, and oil and gas industries. Incorporate ASME, British, European, French, Japanese, Russian, API, NEMA, ANSI, ASCE, AISC, UBC, ISO, and WRC guidelines and design limits.AutoPipe Nuclear

Nuclear Piping Design and Analysis Software

AutoPipe Nuclear enables you to design critical safety pipework to ASME Class 1, 2, or 3 standards. Shorten your plant design and manufacturing cycles while ensuring adherence with approved international nuclear standards. Efficiently demonstrate compliance for projects all over the world with the most extensive design code coverage for new or existing plants. Identify and solve complex problems quickly with fully automated and user defined stress combinations with powerful filtering capabilities. AutoPipe Nuclear gives you the productive graphical CAD interface of AutoPipe for modeling, as well as a graphical view of results with comprehensive nuclear analysis capabilities. AutoPipe Nuclear helps you conform with ASME NQA-1, ISO 9001, CSA N286.7-99, ASME N45.2, and 10CFR50 standards backed by several independent audits by the Nuclear Regulatory Commission (NRC) customers and the Nuclear Procurement Issues Committee (NUPIC). Ensure fast and accurate model creation through reliable data exchange with CAD platforms including OpenPlant, AutoPLANT, PlantSpace, PDS, PDMS, and Smart 3D.